Introduction

Transformers are essential to modern energy systems, bridging the gap between different voltage levels and ensuring smooth electricity flow. Among the various types available, dry-type transformers stand out for their unique design and safety features. This guide will take you through the core aspects of these transformers, exploring their benefits, applications, and why they are a preferred choice for eco-conscious industries and safe residential installations.

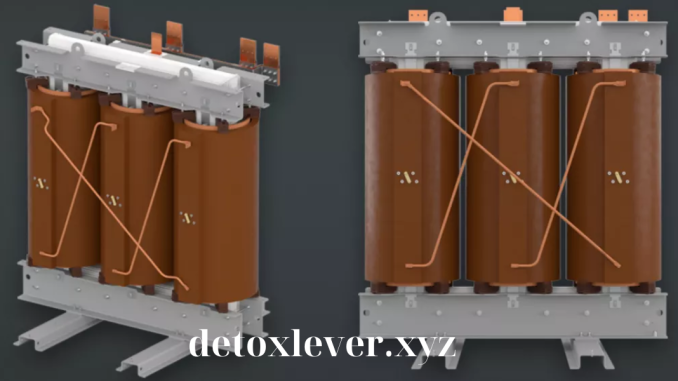

What Are Dry-Type Transformers?

Dry-type transformers differ significantly from their oil-immersed counterparts. Instead of oil, they use air for cooling. This fundamental design choice reduces risks associated with oil leakage and potential fire hazards, making them suitable for places that prioritize safety and environmental impact.

Benefits of Using Dry-Type Transformers

Enhanced Safety

With no combustible materials, these transformers are inherently safer, especially in urban settings or environments with stringent safety regulations. Without the need for oil, risks related to fire hazards are minimized, offering peace of mind to users. This safety factor makes them especially suitable for hospitals, schools, and other public spaces where safety is paramount.

Eco-Friendly Design

Dry-type transformers align well with green building practices. Their air-cooled design minimizes environmental impact, ensuring safer installations even in sensitive locations, like schools, hospitals, and residential areas. Additionally, they support eco-conscious companies in meeting environmental and safety compliance standards, especially in regions with strict environmental guidelines.

Low Maintenance Requirements

Compared to traditional transformers, dry-type variants are relatively low maintenance. Their absence of liquid coolant reduces the need for regular inspections and oil checks, lowering both maintenance costs and downtime. Facilities can often install them in harder-to-access locations, given their durability and reduced maintenance needs.

Energy Efficiency

These transformers are highly efficient in energy usage. Advances in insulation technology and core materials allow for minimal energy loss during operation, benefiting both the environment and users’ electricity bills. Their design and material choices contribute to reduced power wastage, making them a sustainable option that aligns with energy conservation goals.

Applications of Dry-Type Transformers

Dry-type transformers are versatile and find use across various settings, from small residential complexes to large-scale industrial facilities. Their compact, safe, and eco-friendly nature makes them suitable for a range of applications:

Commercial Buildings

Commonly installed in commercial spaces such as shopping malls, offices, and schools, they provide reliable power without posing environmental risks. These spaces often prioritize safety, and with their air-cooled design, dry-type transformers are optimal choices for indoor use where oil-immersed alternatives may not be practical.

Industrial Facilities

Factories and manufacturing plants use these transformers for processes that demand consistent power. Their robust design enables them to withstand harsh conditions. Given that many industrial environments are prone to dust, heat, and occasional moisture, dry-type transformers’ resilience and low maintenance needs make them invaluable.

Renewable Energy Projects

The green energy sector benefits significantly from using dry-type transformers. Wind and solar farms frequently integrate them due to their eco-friendly footprint and efficiency in converting renewable energy into usable power. Their compatibility with renewable setups highlights their role in promoting a cleaner and more sustainable future in energy.

How Dry-Type Transformers Work

A dry-type transformer operates by transferring electrical energy through electromagnetic induction. The core components, such as the primary and secondary windings, are insulated using modern, flame-retardant materials to handle high temperatures safely. Here’s a simplified breakdown of its operation:

- Voltage Conversion:

Electrical energy flows through the primary winding, creating a magnetic field. This field induces a voltage in the secondary winding, stepping up or stepping down the voltage as needed. - Heat Dissipation:

The transformer dissipates heat through natural air circulation or sometimes fans, ensuring the internal components remain at optimal temperatures. - Minimal Loss of Power:

With advances in insulation and core materials, these transformers are designed to minimize energy loss, providing an efficient solution for varied applications.

Key Considerations When Selecting a Dry-Type Transformer

Choosing the right transformer is crucial for optimal performance and safety. Here are some factors to consider:

Voltage Requirements

Match the transformer’s voltage rating with your system’s needs to ensure compatibility and efficiency. Proper voltage matching helps avoid inefficiencies and extends the lifespan of both the transformer and connected equipment.

Environment

Consider the conditions of the installation area. Dry-type transformers are suitable for both indoor and outdoor installations, but extreme weather conditions may affect performance. For installations in humid or highly dusty environments, select models with additional protective features, like specially coated windings.

Cooling Requirements

Depending on your application, consider whether natural air cooling is sufficient or if additional fan-assisted cooling is required. Larger facilities or high-demand areas may benefit from enhanced cooling options to optimize the transformer’s efficiency and lifespan.

Dry-Type Transformers vs. Oil-Immersed Transformers

Both types of transformers serve critical functions in power management, but they

differ in several ways:

Safety and Environmental Impact

Dry-type transformers avoid the risk of oil leaks, making them a safer choice for indoor installations. They are also more environmentally friendly, as they do not use any hazardous materials. This absence of oil eliminates the risk of contamination, which is a concern in water-proximate environments or areas where ecological preservation is vital.

Cost and Maintenance

While initially more expensive, dry-type transformers often have lower lifetime maintenance costs due to their simpler design. The absence of oil eliminates the need for regular fluid checks and replacements. Additionally, maintenance teams can focus more on preventative care rather than oil-level checks, freeing up resources for other facility needs.

Longevity and Durability

Oil-immersed transformers typically have a longer lifespan due to their liquid cooling system. However, advancements in insulation have made dry-type options increasingly durable. With improved materials, these transformers can now withstand higher operating temperatures, helping them to perform reliably even in demanding conditions.

Future Trends in Transformer Technology

With a growing focus on renewable energy and sustainable practices, transformer technology is advancing to meet the demand for efficient, eco-friendly solutions. Innovations are enhancing energy efficiency, reducing weight, and enabling smarter monitoring systems.

Smart Monitoring

New technologies allow transformers to be integrated into smart grids, where sensors monitor performance and predict potential issues, preventing failures. These sensors can detect subtle changes in temperature or load that may indicate early signs of wear or malfunction, enabling proactive maintenance.

Advanced Insulation Materials

The development of better insulation is reducing power loss and improving thermal management, helping these transformers operate more efficiently in extreme conditions. Improved insulation also makes these units more resistant to temperature spikes, making them more reliable over extended operational periods.

Integration with Renewable Energy Sources

Transformers compatible with renewable systems support the global shift toward cleaner energy sources. As renewable energy projects continue to expand, the demand for efficient, environmentally-friendly transformers will only grow. Their role in harnessing green power and reducing carbon emissions places them at the forefront of sustainable infrastructure.

Conclusion

Dry-type transformers offer a host of benefits, from improved safety and energy efficiency to environmental friendliness. Their applications span commercial, industrial, and renewable energy sectors, making them a versatile choice in modern power systems. As innovations continue, these transformers will likely become even more integral to energy-efficient, sustainable infrastructure.

By choosing these air-cooled transformers, businesses and industries align themselves with sustainable energy goals, ensuring reliable, safe, and efficient power distribution. With minimal maintenance needs and enhanced environmental safety, they represent a forward-thinking solution for today’s energy challenges. As technology advances, we can expect even more innovations that make these transformers indispensable in a world focused on energy efficiency and sustainability.

Leave a Reply